Ecocera co., ltd.

TEL : 82-2-2083-8311

FAX : 82-2-2083-8310

#1812

298, Beotkkot-ro

Geumcheon-gu, Seoul,

Republic of Korea

KOREA (Zip code : 08510)

Contact :

ecocera@ecocera.co.kr

© 2016 ECOCERA co.,ltd.

All Rights Reserved.

Why we need GI-180 Block Lining System

Home > For chimney Design > Why we need GI-180 Block Lining System

I. Why we need GI-180 Block Lining System at this time?

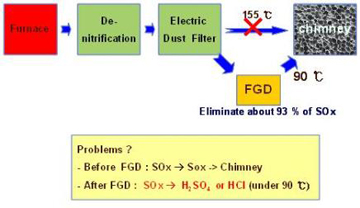

In the past when environment preservation had not been a major issue in the society, industries using fossil fuels such as thermal power plants, operated it without desulfurization facilities, using fireproof materials such as corbel-based acid resisting and fire proof bricks as lining material of chimneys to exhaust flue gas of which temperature ranges from 125 to 180 degree C. But as environment preservation has become one of major concerns in every society around the world, the desulfurization facility has been mandatorily adopted for keeping air and human health from further pollution. In this case,the exhaust gas temperature ranges from 150 to 160 degree C.and it drops down to 85 ~ 90 degree C as soon as the gas passes through the desulfurization facility and G.G.H. At this stage, strong acid gas high in temperature and rich in moisture is produced due to drastic changes in temperature of flue

gas. In this connection, it requires fireproof material that has additional definite quality of acid resistance and moisture proof. But existing corbel-based acid resisting and fireproof brick liners for chimneys are apt to developing cracks from drastic temperature fluctuation in chimney structure materials and inappropriate spacing among corbels. On top of this, as insulation effect reduces generally from partial damages in lining system, concrete could develop more serious cracks, and consequently concrete structure is rapidly weakened by its neutralization and degradation from sulfur dioxide gas. All of these factors seriously influence chimney structure to shorten lifetime in service. And Bumtite C-14 has been widely used as castable mortal for steel chimneys so far. But in general, the acid resistance of the castable rapidly decreases after 10 years operation because high corrosive acid, Fe₂O₃ increases from 2 to 12 % in the chimney structure. And when the desulfurization facility is additionally constructed to existing plant, complete internal environment changes in the chimney happen, and the damaged part of the existing chimney structure would degrade rapidly and significantly, curtailing the life cycle of the chimney structure. Thus, reinforcing work for the internal part of chimney must be implemented definitely. In this case, the suitable material to reinforcing work of certain chimney should withstand harsh thermal shock from abrupt and rapid temperature changes as well as severe acidic condition within the chimney. BOROSILICATE CELLULAR GLASS BLOCK is the ideal clue for such renovation and reinforcement works, one of which was carried out by KEPCO (Korea Electric Power Corporation).

- Fig.1 The Mechanism of Corrosion in the FGD Stack inner

- Fig. 2 Corrosion of Traditional material in the FGD Stack inner

Ⅱ. Features of GI-180 Block Lining System

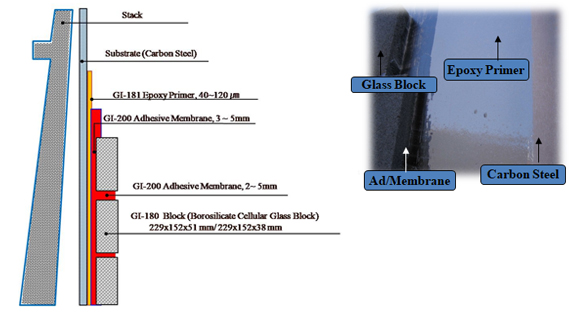

Fig. 4 Materials for chimney lining

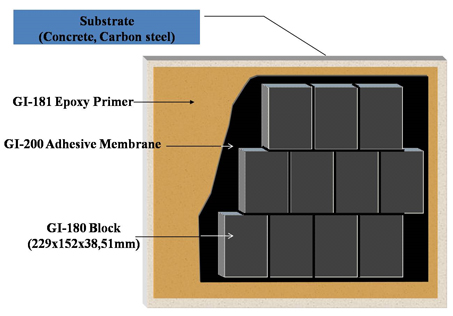

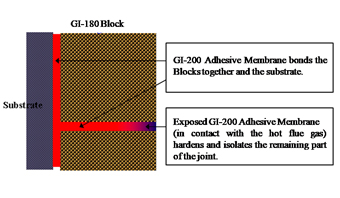

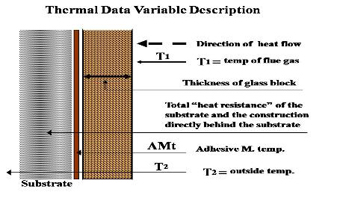

GI-180 Block Lining System is comprised of GI-180 Block, GI-200 Adhesive Membrane, GI-181 Epoxy Primer, repair material and Waterproof flooring material. Glass blocks protect substrates from corrosive gases and liquids while primer & membrane works as bonding material of glass blocks to substrates as well as protection material of substrates.

- *GI-181 Epoxy Primer is designed for

carbon steel,stainless steels and other substrates.

Ⅲ.Comparison table for properties with others FGD stack inner lining system

The first point is GI-180 Block Lining System is very much reliable and proved already. In addition, it needs less initial investment and comparatively low maintenance cost with longer service lifetime. It gives cost reduction to customers using alloy material and more reliable system to customers using organic coating material.

| Organic Coatings (epoxy,vinylester) |

Acid-Resistant Gunite Materials |

Alloy Materials | ECOCERA GI-180 Block | |

|---|---|---|---|---|

| Advantages | · Good acid-resisting qualities | · Good acid-resisting qualities | · Very good acid-resisting qualities | · Very good acid-resisting qualities (Chlorides, H2SO4) |

| · Excellent Thermal Shock Resistance | ||||

| · Low Cost | · Light weight | |||

| · Good application (Various surface) | ||||

| · Light Weight | · None water permeability | |||

| · Low maintenance cost | ||||

| Dis-advantages | · Crack of lining | · High cost | · Brittle | |

| · Porosity | ||||

| · Weak insulation in wet weather | ||||

| · Short service life (3-6 years) | · Require of insulation | |||

| · Heavy weight (100Kg/m2) | · Limited material for maintenance work |

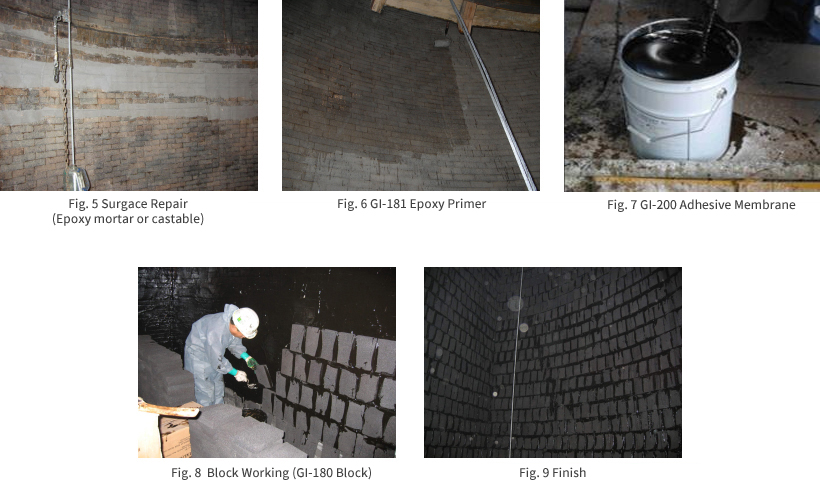

Ⅳ. Application GI-180 Block Lining System

4.1 Materials for installation

- Epoxy Primer : GI-181

- Adhesive Membrane : GI-200

- Borosilicate Cellular Glass Block : GI-180 Block

4.2 Construction Process